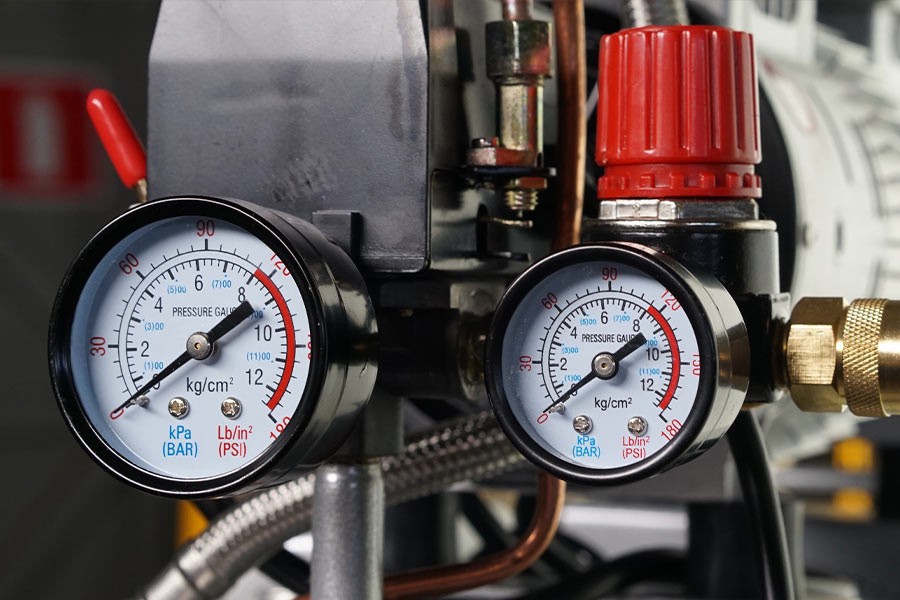

Therefore, you have determined the dial and connection size required for the gauge. You even know your preference for wetting materials. But what about if the gauge is dried or filled with liquid? What are the benefits of Glycerine filled manometer? Is there something negative? Believe it or not, determining this feature may confuse many customers. No more confusion – our Vacuum pressure gauge Manufacturers will explain to you all the knowledge about why gauges are filled with liquid.

In short, during vibration applications, liquid-filled pressure gauges are strictly used as an inexpensive method to stabilize the needle and lubricate the inside of the pressure gauge. The most commonly used filling fluids are glycerin and silicone. Glycerin is used in approximately 95% of all liquid filling applications and is usually "standard". The reason for using these liquids is because they are more viscous and their thickness helps keep the needle stable. Some pressure gauges will dry out, but you only need to fill the sealed pressure gauge case through the filling port (usually at the top), and then reinsert the filling plug when you are done.

As with any decision, when deciding what is best for you, you should outweigh your own pros and cons. Let us break it down for you here:

Benefits of Glycerine filled manometer

It stabilizes the needle. If there is no liquid to fill the gauge, the needle will pop up irregularly, making it difficult to pinpoint the correct position of the needle on the gauge.

This is an inexpensive solution, and in many cases has become the standard configuration of gauges

By damping and lubricating the mechanical parts of the pressure gauge, it helps to extend the service life of the pressure gauge.

A negative number of liquid filling meter

Due to exposure to ultraviolet rays or sharp changes in temperature, glycerin will change color (black or yellow) over time

Standard glycerin is actually only effective below 20 degrees Fahrenheit. Not recommended for use in cold environments

Leakage risk

In this case, because the temperature change (usually very small, about 1 PSI) will affect the expansion and contraction of the fluid, thereby affecting the accuracy of the reading, and causing the needle to deviate from the zero position, the pressure will be formed

Although some of these negative factors seem to be a deal-breaking agreement, there are some simple solutions to these problems. We will start with the color change. If you are concerned about potential discoloration, choose silicone instead of glycerin. Silicone resin has high-temperature resistance, so it is not easily affected by ultraviolet rays. Therefore, silicone tends to retain color longer than glycerin.

If your application has a very low temperature of 0 degrees or lower, you can use silicone or a mixture of glycerin and distilled water instead of pure glycerin. Both fluids will allow the temperature to be reduced to -40 degrees Fahrenheit.

As for leakage, this is always a risk for pressure gauges filled with liquid, but the risk is very low. The chance of leakage depends on the quality of the meter you are using and the application. If you are most concerned about leakage, to reduce the risk, use a crimped baffle type instead of a bayonet, because the crimped baffle permanently fixes the gasket in place and is unlikely to loosen in the field or due to human error. Thirdly, due to improvements in manufacturing technology and standards, the risk of leakage is now very low. All Kodiak pressure gauges follow the ASME B40.1 standard to ensure that the pressure we provide is expressed to the highest quality standards.

Last but not least, let's talk about the accumulated pressure. Pressure may form inside the pressure gauge, which is natural for a pressure gauge filled with liquid. The accumulated pressure (usually very small) can sometimes cause the pointer to move away from zero and/or make the pressure gauge reading incorrect + or – 2-4%. In order to reduce the pressure, the meter can be suppressed by slightly lifting the filling plug. When you are done, you will see the pointer move back to zero.