When the applied pressure reaches the upper limit scale value of the pressure gauge, the pointer of the pressure gauge still does not move or moves seldom.

Solving the problem in the use of the pressure gauge indicates that the pressure is not transmitted to the spring tube. First check whether the sealing gasket connected to the pressure gauge calibrator blocks the channel at the joint. If there is no problem with the connection, it proves that the inside of the pressure gauge is blocked and should be cleaned.

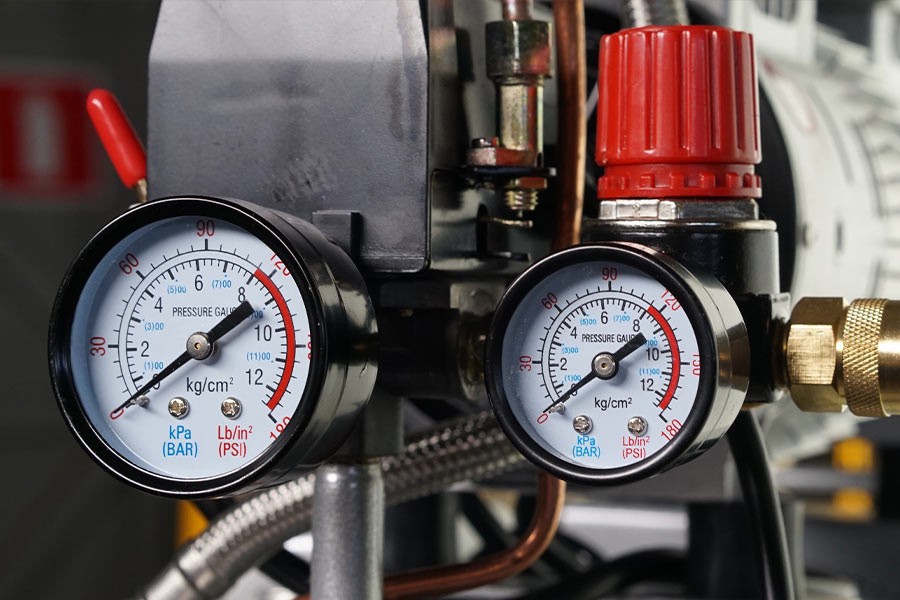

When we use pressure gauges, we often encounter the following problems (with solutions):

1. After the pressure is removed, the pointer cannot return to zero

1) If the pointer is bent or loose, it can be corrected with tweezers and tapped tightly after verification.

2) If the balance spring torque is insufficient, the meshing of the central gear and the sector gear can be disengaged, and the central gear shaft can be rotated counterclockwise to increase the balance spring reaction torque.

2. The pointer of the pressure gauge jumps or does not rotate

1) There is friction between the pointer and 3) the transmission gear. Adjust the meshing gap of the transmission gear.

The surface glass or the dial will rub against each other. The pointer can be corrected by thickening the washer under the glass or making the pointer shaft hole larger.

2) The central gear shaft is bent, the shaft diameter is not concentric, and does not coincide. The gear can be removed and straightened with a wooden hammer or straightened with flat-nose pliers.

3) There is dirt in the meshing area of the two gears, the two gears can be removed for cleaning.

4) If the movable screw between the connecting rod and the sector gear is inactive or loosened, the thickness of the connecting rod can be thinned with a file.

3. Only a certain verification point is out of tolerance

1) On which scale is found to be out of tolerance, stop on which scale. Check the fit of the parts on the scale point, whether the drive shaft hole is blocked; whether the connecting rod is flexible; whether the tooth meshing point is damaged, foreign objects, etc., to be removed.

2) When a positive error occurs at a certain point, it is often due to dirt and burrs at the tooth meshing point; when a negative error occurs, it is mostly due to tooth shape damage or tooth damage. For severely damaged teeth, new parts should be replaced. When there is no new part to replace, the center wheel has broken teeth and the meshing position can be changed, so that the broken teeth can avoid transmission. If the sector wheels have broken teeth, they cannot be adjusted and must be replaced with new ones.

How to solve the problems in the use of pressure gauges

4. In use, the indication cannot be stable and the pressure drops significantly

At this time, first check whether the connection between the pressure gauge and the pressure gauge calibrator is leaking. If there is no oil leakage and the calibrator is intact, it indicates that there is leakage inside the spring tube. The scale plate should be removed for further inspection.

1) The base itself has blisters, which will gradually leak after long-term use. The base of the same specification needs to be replaced, and the low pressure measurement can be repaired.

2) After long-term pulse pressure, the spring tube is fatigued or there is leakage in the sealing parts at both ends. The two sealed parts can be repaired or re-tightened. If it breaks, the spring tube will be scrapped.

3) Long-term corrosion by the measured medium, the spring tube causes leakage. It is necessary to select a pressure gauge with corrosion resistance, and replace the spring tube if necessary.

4) There are obvious cracks or breaks due to the quality of the spring tube. It is necessary to replace high-quality spring tubes of the same specification and take corresponding protective measures.

5) Improper selection of specifications, the measured pressure is close to the upper limit of the gauge, fatigue and rupture due to long-term pressure. The pressure gauge of the appropriate specification should be carefully selected, and if the spring tube is broken, the tube of the same specification should be updated.

5. Uneven pressure indication error

1) The spring tube fails due to deformation, and the displacement is not proportional to the pressure. The spring tube needs to be replaced.

2) The transmission ratio of the free end of the spring tube, the sector gear and the wheel rod is not adjusted properly, and needs to be checked and adjusted again.

3) The combination position of the gear clamp plate and the bottom plate is wrong. The coupling screw should be loosened to drive the splint in a counterclockwise direction.

4) The pointer displacement size causes the balance spring to be unevenly tightened to the front or rear. Adjust the balance of the balance spring to rotate the center gear.

6. In the process of pressurization, the pressure gauge pointer jumps, sluggish, and deteriorates greatly.

It means that the transmission mechanism has friction, and the instrument must be disassembled to check the meshing condition of the transmission mechanism and perform necessary treatment.

7. The error of the checked meter always increases or decreases by a fixed value

According to the characteristics of this error, we can draw a conclusion: as the pressure increases, the error increases or decreases by the same amount. In the entire measurement range, the pointer reading is always a fixed value different from the standard display value. This is a systematic error caused by incorrectly installed pointers. We don’t have to worry about it. Because it is very easy to adjust this kind of error, just start the needle and adjust again.