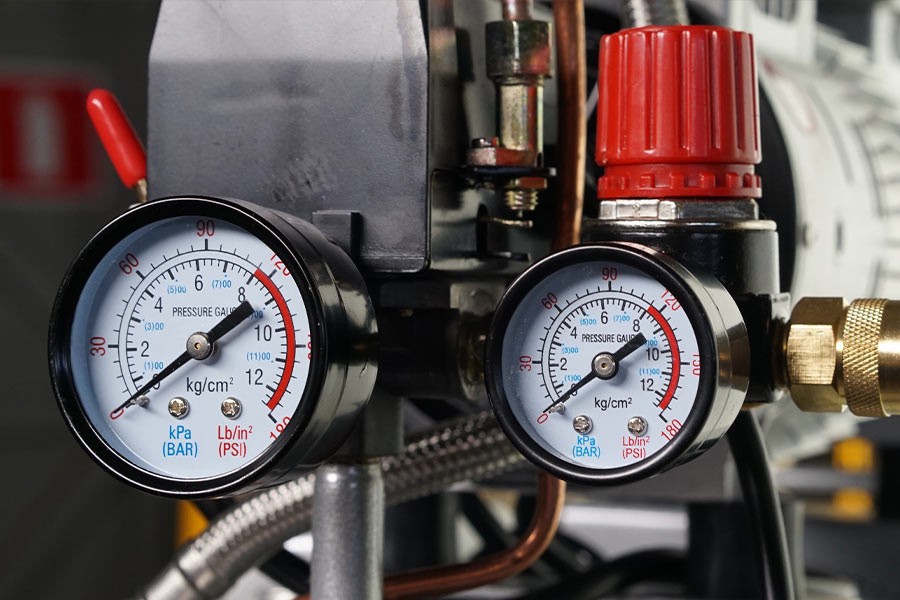

Modern pressure gauges are very robust and accurate, but they lose accuracy over time. This means that if you want to continue to provide accurate readings, the meter must be calibrated regularly. It is generally recommended to calibrate the gauge before installation as part of a preventive maintenance plan, during downtime, and during annual ISO audits.

Glycerine filled pressure gauge calibration laboratory

Glycerine-filled pressure gauge has an ISO 17025 certified full-service calibration laboratory that can help you calibrate the pressure gauge or repair or reinstall any damaged pressure gauge. For damaged equipment, our experienced technicians can replace gauges, windows, and pointers. They can also replace and reset the pointer and make necessary adjustments to restore your pressure gauge to the published accuracy specifications. All returned products are recalibrated before being shipped back to the customer.

Instrument shelf life and calibration interval

The pressure gauge manufacturer's pressure gauge is usually calibrated before leaving the manufacturer. Meters that are properly stored in a warehouse or parts storage room may require a period of time without recalibration. It is recommended to perform accuracy verification before installation because the meter will not remain calibrated indefinitely. After installation, it is recommended to calibrate the pressure gauge at least once a year. Regardless of the application, this applies to all meters in all industries. Many companies, especially those in the pharmaceutical, biotechnology, and medical equipment sectors, perform pressure gauge calibration every three to six months to maintain process optimization and prevent costly quality control errors. The consequences of quality control errors in these industries are very serious, including the need to discard entire production batches, large fines, and even direct FDA supervision. Therefore, pressure gauge calibration is a top priority. One or two small quality control errors can cost millions of dollars.

Factory pressure gauge calibration cycle

Most processing plants rotate pressure gauges and other instruments according to the calibration cycle or closed quarterly or semi-annually. Spare pressure gauges (parts on the shelf or in stock) are calibrated before the planned installation. Then, schedule the removed equipment for calibration so that it can be used in the next cycle. Setting regular pressure gauge calibration cycles can minimize the chance of inaccurate pressure readings and improve process monitoring and supervision. If you have a Glycerine-filled pressure gauge or other instruments that need to be calibrated, please contact a professional calibration laboratory to complete the work correctly. In most cases, we can return the calibration and/or repair gauge to you within five working days.