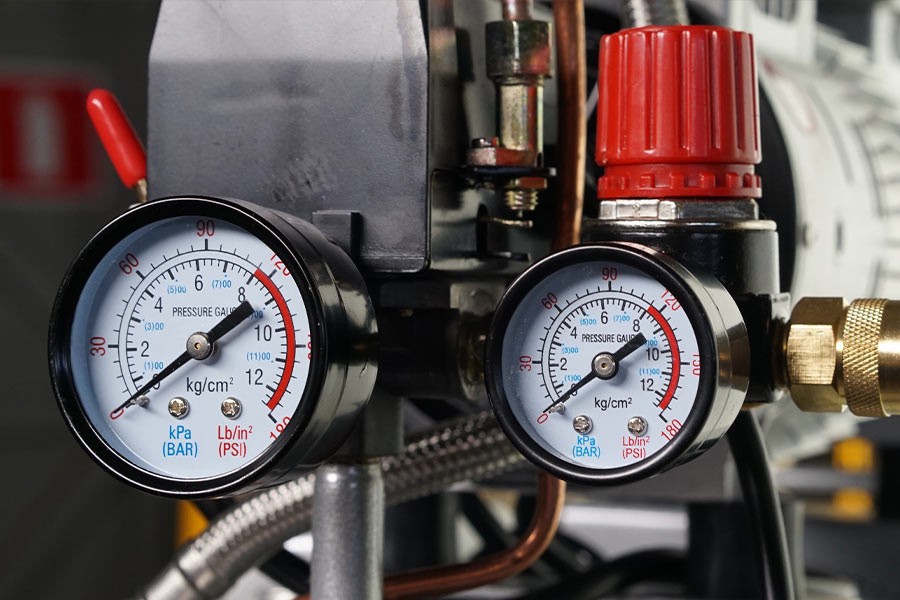

When the pressure gauge is connected to the pipe, a bend should be added between the pressure gauge and the pipe connection. Why is this? What does this do? Let us take a look!

The thing that connects the pressure gauge to the pipe is the pressure gauge bend (also referred to as the gauge bend) , the official name is the buffer tube. Used to connect the pressure gauge and the pressure gauge measuring equipment or pipe fittings, used to buffer the instantaneous impact of the measured medium on the pressure gauge spring tube, which can well protect the mechanical structure of the digital display or the pressure sensor from damage ,Extended service life.

There are many kinds of materials for the pipes. To measure different media, you need to choose buffer tubes of different materials to ensure the accuracy of the measurement and the normal operation of the measurement system.

The scientific name of this elbow is called condensing pipe or siphon . According to "HG/T20581-2012" version HK03 pressure/differential pressure measuring instrument piping connection atlas description 6.4 installation instructions introduce "For steam and other condensable hot gases, and when When the temperature of the medium exceeds 60℃, the pressure gauge installed on the spot should use the installation drawing with a condenser (or siphon). The purpose is to passivate the gas medium to prevent damage to the instrument.

Of course, the "SH/T3104" instrument installation design specification also has similar instructions.

There are two types of pressure gauge bends: one is a circular bend and the other is a U-shaped bend.

The purpose of the pressure gauge bend is to protect the internal transmission mechanism of the gauge from the damage of the medium temperature and the corrosiveness of the medium. Generally, if the medium is corrosive to a certain extent, a pressure gauge bend must be installed. When the temperature of the medium is greater than 60°C, a pressure gauge bend must be installed. If the pressure gauge is installed on a clean drinking water system, there is no need to install it.

It also has the function of reducing vibration and impact, and also has a certain heat dissipation effect on the higher temperature medium to protect the pressure gauge and reduce the temperature influence error of the pressure gauge. The damping screw at the orifice of some pressure gauge joints has a throttling buffer effect by reducing the flow area, which is mainly useful for medium pressure pulses.