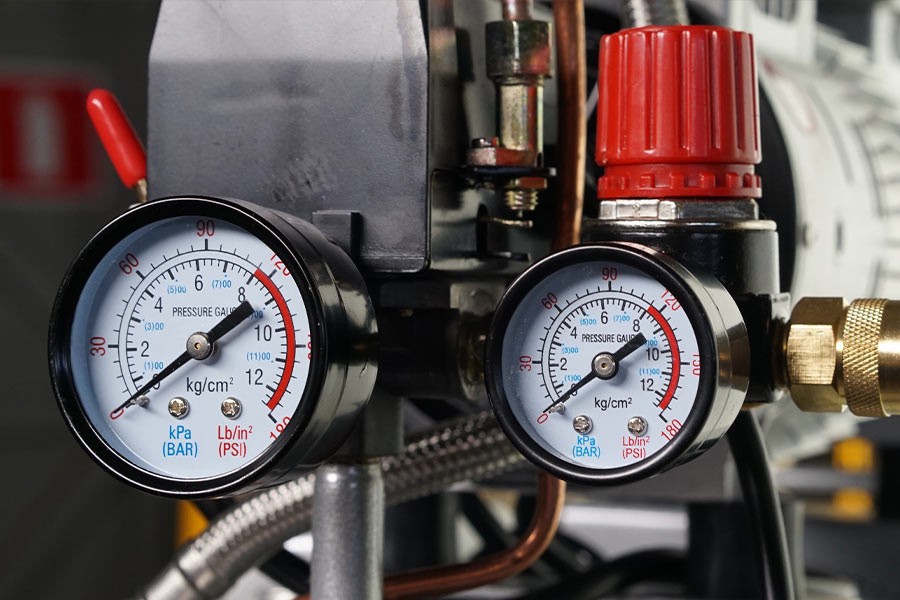

Maintaining a silicone-filled pressure gauge is important to ensure that it continues to provide accurate and reliable pressure readings. Here are some general maintenance tips for a silicone-filled pressure gauge:

1. Inspect the gauge regularly: Regularly inspect the gauge for any signs of damage, such as cracks or dents, and make sure the glass cover is clean and not scratched.

2. Check the silicone fluid level: Check the silicone fluid level in the gauge periodically to ensure that it has not leaked out. If the level is low, you can add more silicone fluid as per the manufacturer's instructions.

3. Calibrate the gauge: Periodically calibrate the gauge to ensure that it is providing accurate readings. This can be done using a calibration tool or by comparing the gauge reading to another calibrated gauge.

4. Check the connection: Make sure that the connection between the gauge and the system being measured is secure and tight to prevent leaks.

5. Protect the gauge: Protect the gauge from extreme temperatures, corrosive materials, and physical damage.

6. Replace damaged parts: If any part of the gauge is damaged, replace it promptly to avoid inaccurate readings or further damage to the gauge.

By following these maintenance tips, you can ensure that your silicone-filled pressure gauge remains in good condition and provides accurate and reliable pressure readings over its lifespan.

Cixi Oukate Instrument Technology Co., Ltd. not only has silicone-filled pressure gauges but also Glycerine filled pressure gauges, welcome to visit our official website.