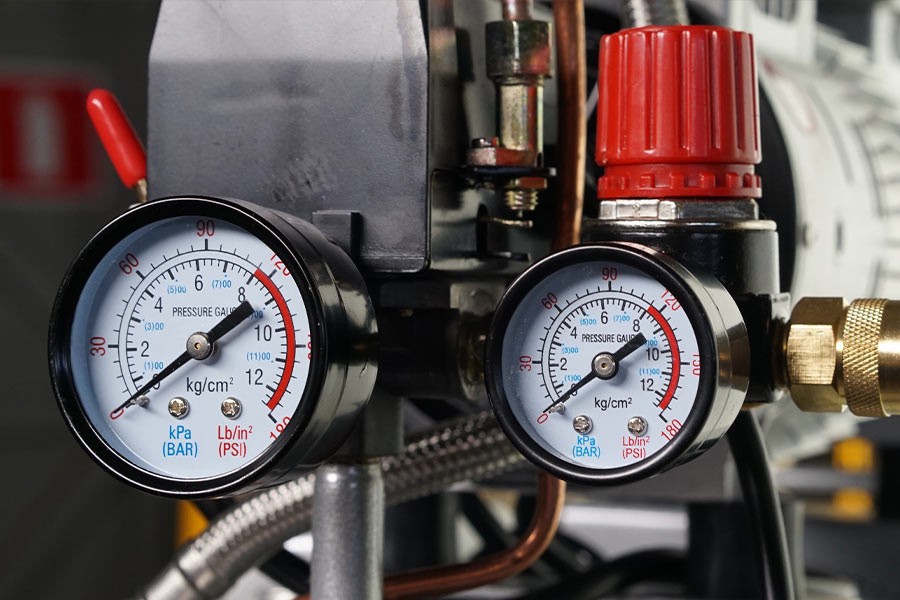

As a pressure measuring instrument with elastic elements as sensitive components, pressure gauges have been widely used in the industrial field with the technical advantages of high accuracy, convenient detection and simple operation since their development and application.

Since pressure gauges are mainly used for important links in the industrial field, once the pressure gauge is inaccurate in measurement verification, it will inevitably have a great impact on the stability and safety of products in the industrial field. With the further application and promotion of pressure gauges, the accuracy of pressure gauge verification has received extensive attention. How to perform correct metrological verification and calibration of pressure gauges is a very prominent problem in the development process of pressure gauges.

The pressure gauge uses the elastic element as the sensitive element for sensing, which can measure and indicate the pressure of the instrument higher than the ambient pressure so that the measuring personnel can know the pressure value of the measuring instrument through the display of the pressure change. According to the classification of the use of pressure gauges, pressure gauges can be divided into ordinary pressure gauges, ammonia pressure gauges, oxygen pressure gauges, shock-resistant pressure gauges, electric contact pressure gauges, digital tight pressure gauges and double-needle pressure gauges. When applying, it is necessary to select the type of pressure gauge according to the requirements of the measuring instrument. Under normal circumstances, the maximum range scale of the pressure gauge is 1.5-3.0 times the maximum working pressure of the container, but in order to ensure the accuracy and safety of the pressure gauge pressure detection, the actual measurement needs to be controlled at about 2 times, and the diameter of the pressure gauge cannot exceed a range of 100 mm.

The rapid development of industrialization and technology has increased the experimental demand for pressure gauges in the industrial field. Further optimization of the pressure gauge detection level. In this regard, when using a pressure gauge for pressure verification, it is necessary to select a reasonable type of pressure gauge according to the purpose and scope of the pressure verification, and after the selection is completed, install the pressure gauge according to the requirements of the specification. To implement the metrological verification of pressure gauges, professional staff must be used to adjust the measurement, so that they can complete the detection of various types of pressure gauges according to the requirements of standardized operation steps and procedures, thereby minimizing the occurrence of pressure gauge failures.

Cixi Oukate Instrument Technology Co.,Ltd. is a pressure gauge factory and pressure type thermometer and other products, welcome to visit our official website.